Automated processes are the Lab’s turning point to reach new heights of flexibility, quality, process management and optimization, and of course prestige.

Copan will take you by hand, wipe out all uncertainties, and guide you through this breakthrough change!

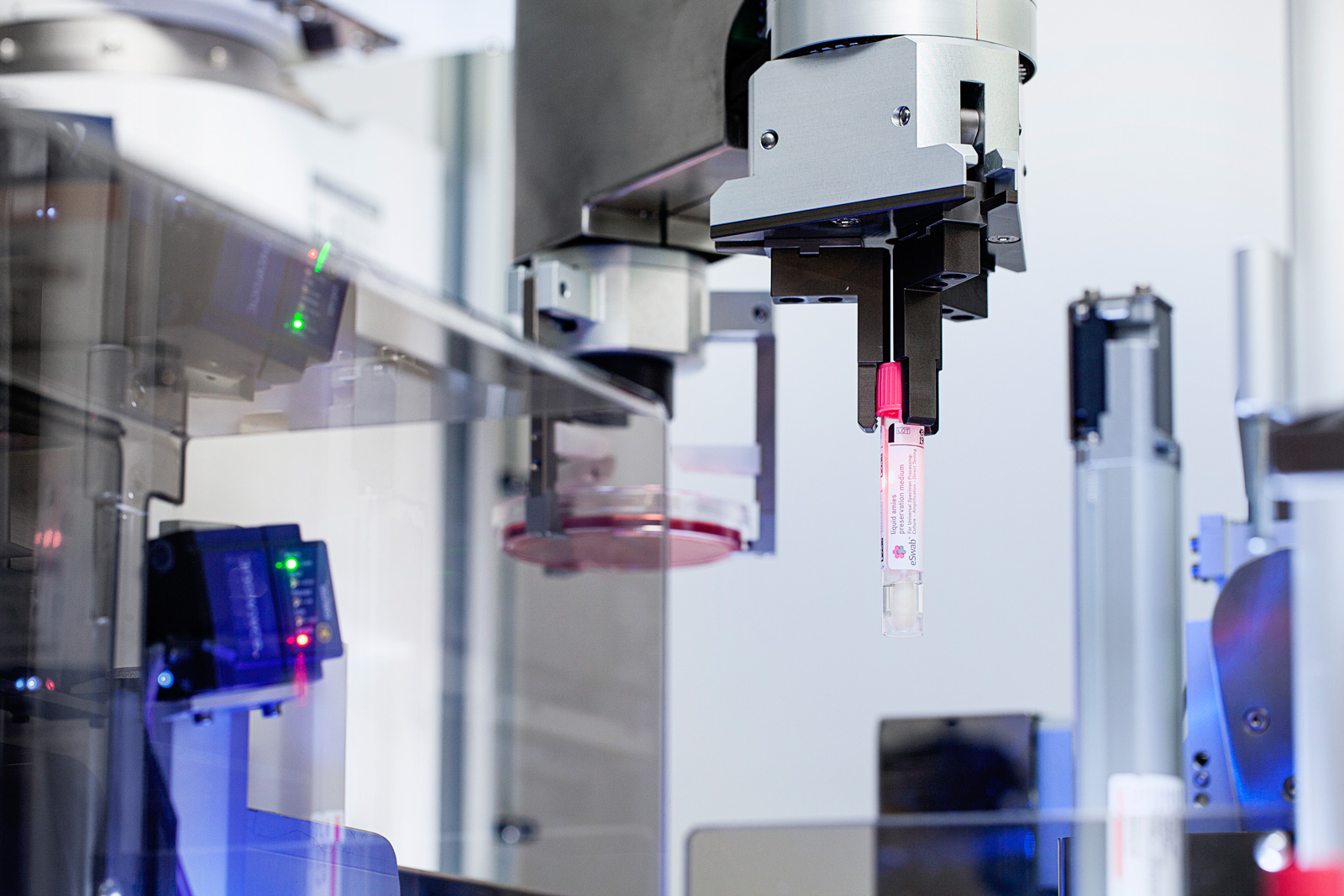

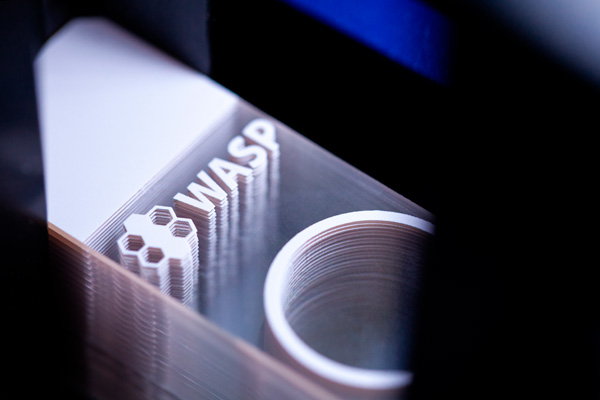

From collection and transport to specimen processing. Copan’s liquid-based approach is the key to success in both steps of preanalytics: the first leverages the advantages of the liquid phase by maximizing sample release and transforming solid, semi-solid, and viscous samples into a liquid format. On the other side, WASP® reaches maximum performance by focusing on specific technical features that gain the best from liquid samples.

From the installation of the first generation to the most recent, we listen and partner with our customers in the microbiology community.

This is what earned us the trust and reliance of hundreds of laboratories around the world.

Let WASP® be your best support for automatic bacteriology sample preparation.

Utilising industry best practices, and more than 10 years of market presence, it works in synergy with technologists that can be free to attend more pressing tasks: culture interpretation.

Avoid workflow disruptions through continuous and random loading: the system will communicate with LIS to discriminate the correct workup and complete it without any other interaction.

Enjoy full traceability of samples* and downstream workups like plates, microscope slides, and broths thanks to LIS data integration, barcode readers, and onboard printer.

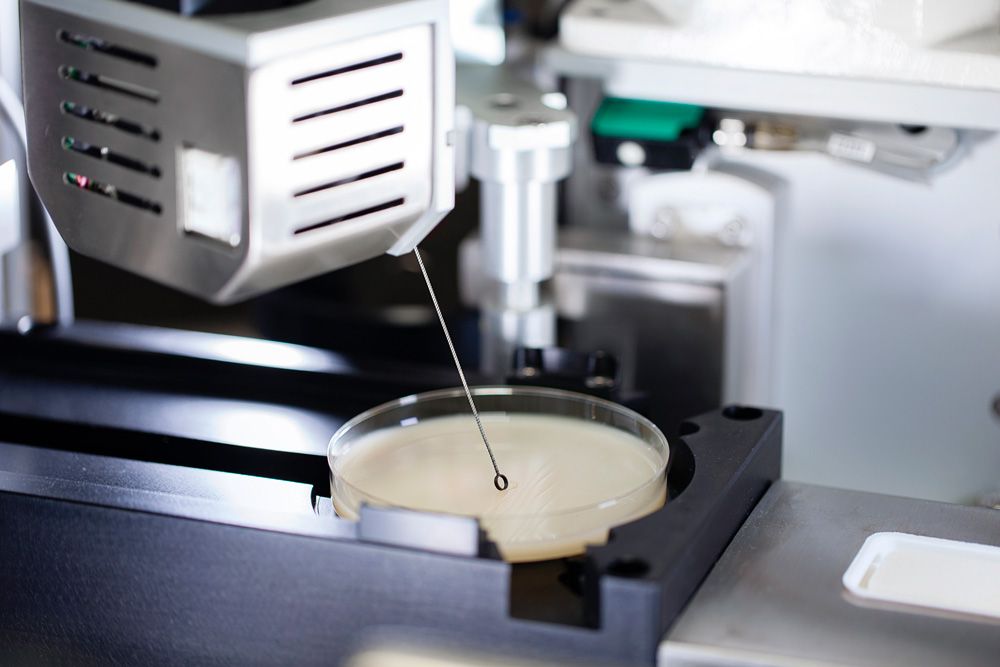

Each process equal to the other, each operation precisely defined. We set a new frame of reference, to drive, manage, understand and optimize the lab workflows.

40+ streaking patterns available, different and reusable inoculation loop sizes (1ul, 10ul, 30ul), dedicated loops for dual streaking. All features are LIS driven for automatic selection and change of streaking patterns and adequate loop.

HEPA filtration system together with anti-drop technical solutions are WASP® key features to minimize contamination and cross-contamination risks.

Enhance your workflow management by integrating modules to automatize Broth Inoculations and Microscope Slide preparation.

Takes care of the inoculation of enrichment broths or other transport systems, to address the need for parallel tests starting from a single sample.

Takes care of microscope slide smearing and fixation. It also boasts a sophisticated laser system for anti-solvent label printing.

Empowered by specific WASP® protocols, Radian® is the WASPLab® module dedicated to the full automation and interpretation of Disk Diffusion Antibiotic Susceptibility Testing.

Never stop thinking about the future, as WASP® is just the first ring of the Full Lab Automation ecosystem! Microbiology 4.0 is the synonym of advancement and power of technology: WASPLab® is directly linked with WASP® and it is the portal to microbiology digitalization.

Build up your Lab dream, module by module you can scale up quality, productivity, and medical value.

Write us to satisfy your curiosity, get information or start a great collaboration!

Use our search tool and be surprised by how easy it is to get right to the point.